COST-OPTIMISED MATERIAL HANDLING FLEET CONCEPTS

How well do you know your material handling fleet? What is the total cost per vehicle? Our experts can develop customised and cost-optimised fleet concepts by calculating the optimal useful life of each vehicle category based on TCO aspects. Repair costs, downtime, and maintenance work increase disproportionately once a certain number of operating hours has been reached. The optimal useful life varies from manufacturer to manufacturer and from product to product. The wear and tear on an electric pallet truck, for example, is different to that of a counterbalanced truck with a diesel engine.

Flexible contracts

Are you looking to switch manufacturers, but without the hassle of new contracts and protracted negotiations? Simply order your new vehicles and we will integrate them into the existing agreements. These contracts are and will remain perfectly tailored to your company, of course, both in Singapore and internationally.

FACT-BASED RECOMMENDATIONS

Our experts know the different brands, types, and classes of material handling vehicles. Each of them has many years of industry experience and a sound knowledge of the technology and its application. As independent technology managers, we give recommendations based on clear figures, facts, and benchmark comparisons. This is how we achieve optimal fleet structures and contracts geared towards TCO, with potential savings of up to 50 per cent.

A strong partner for international fleets

If you operate internationally, then you probably know how demanding it is to cost-effectively monitor and control an equipment fleet on a large scale. That is why we have evolved into a strong international partner for our customers. Whether you operate in Singapore, Australia, Europe, the US, or Mexico or have different regional manufacturers and service partners, we are there for you.

We cover your entire international fleet in a single contract, and you can meet all costs with a flat monthly payment if you prefer. Flexible and transparent, across countries, manufacturers, and partners, and in compliance with regional tax laws and legal provisions. You can enjoy the long-term benefits of an internationally uniform process for managing your material handling vehicles, as well as lower costs and less administrative effort.

Technological and administrative transparency for your equipment and data

How many vehicles do you have? From which manufacturers? What is the capacity utilisation? How high are the total costs? What type of lift masts are installed, and what type of batteries? Which contract is running out, and when? Our digital platform tesma creates transparency by bringing together administrative and technical data. Its smart reporting features allow you to conduct extensive structural and usage analysis, and enable precise investment planning based on vehicle, location, and country. It also enables the precise and cause-related allocation of all expenses.

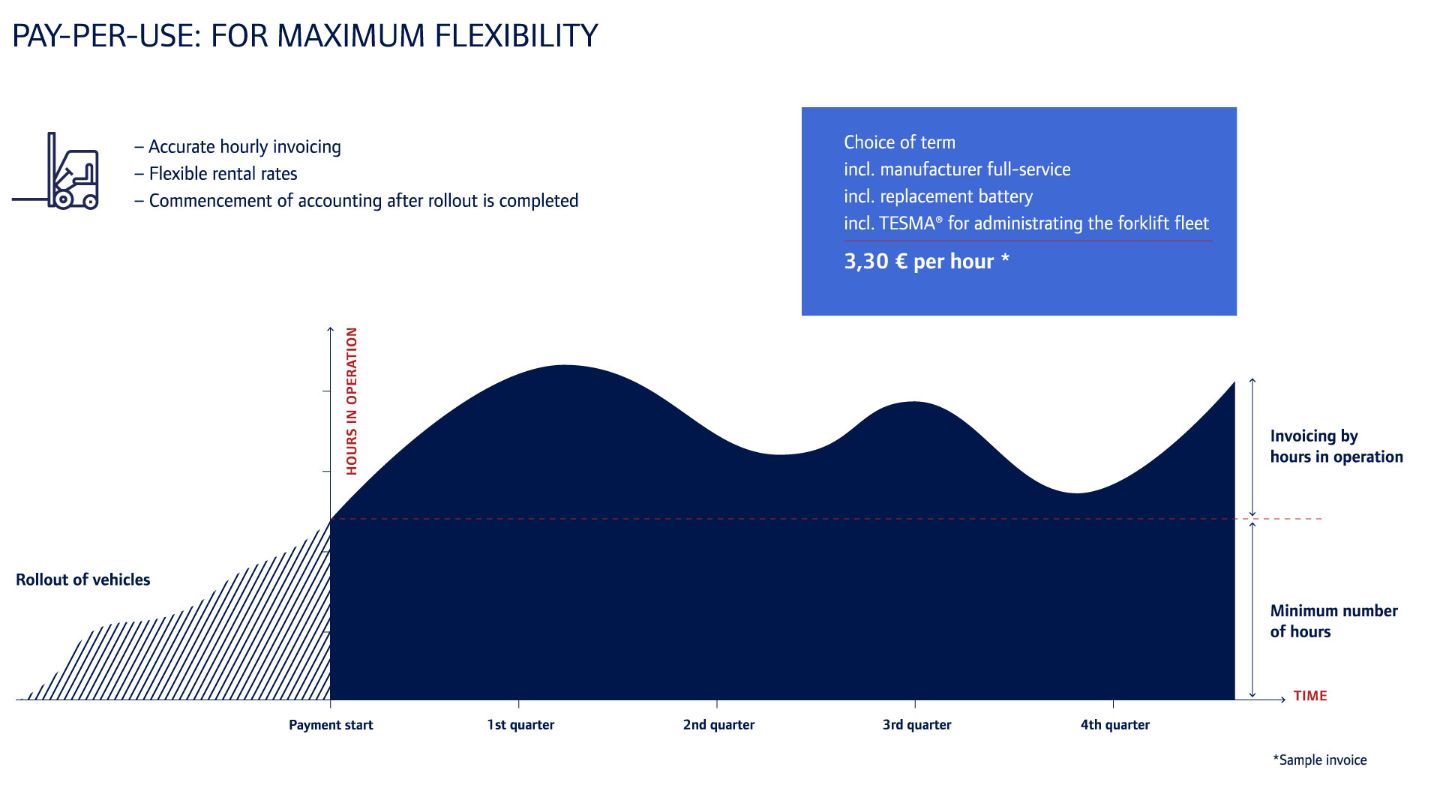

Instalments based on capacity utilisation

Do you want greater flexibility in your fleet management? We’ve got it covered. For example, we can base your lease instalments on your capacity utilisation by billing you per operating hour (pay-by-the-hour). If the number of hours falls, so does your monthly lease instalment. This positively impacts your cash flow and allows you to feel more relaxed about fluctuating usage. You also have the option to adapt the size of your fleet to your needs, while early-return models make it easier to upgrade your equipment. We will combine all of this into a transparent and predictable lease instalment under one contract. You can also integrate your existing material handling vehicles into the contract by taking advantage of our sale and leaseback model.

CONTACT US NOW!

If you have any questions or would like more detailed information, then our experts will be happy to help.

.jpg)